Did you know that in Australia and New Zealand, raisins are sometimes humorously referred to as “sultanas”? While in many other English-speaking countries, “sultanas” specifically refer to a type of raisin made from a particular grape variety, in Australia and New Zealand, the term is often used interchangeably with “raisins.” So, if you ever find yourself Down Under and someone mentions sultanas, don’t be surprised if they’re actually talking about raisins! It’s one of those quirky linguistic differences that can lead to amusing misunderstandings.

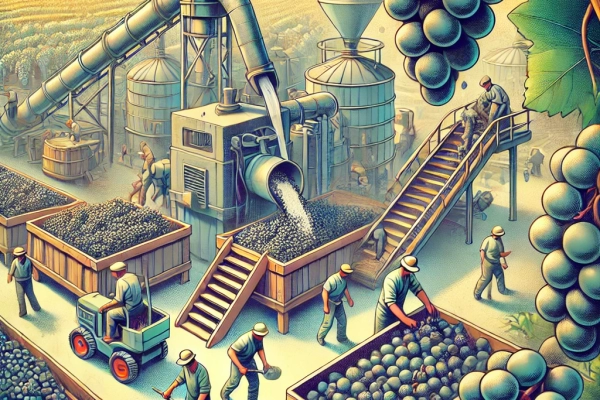

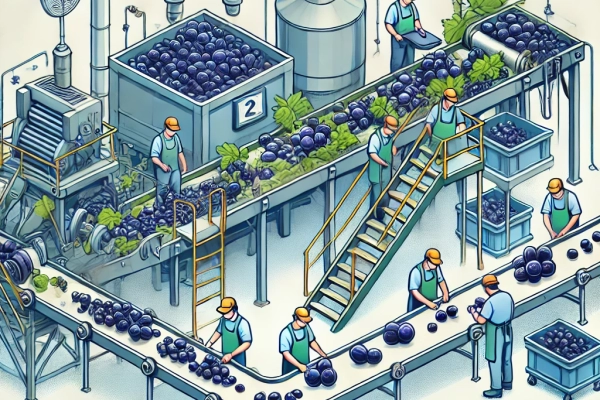

Sorting of Detached Berries

After debunching, the individual grapes need to be sorted. This sorting process involves removing any damaged, unripe, or undesirable berries.

Sorting ensures that only high-quality grapes proceed to the next stages of processing.

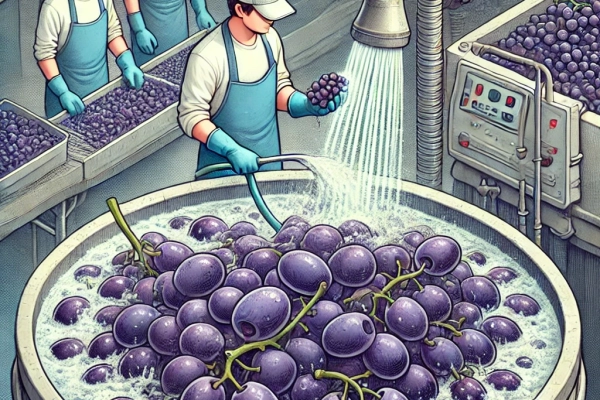

Washing

Once sorted, the grapes are thoroughly washed to remove any dirt, debris, or residues from pesticides.

Washing helps to ensure that the grapes are clean and ready for further processing.

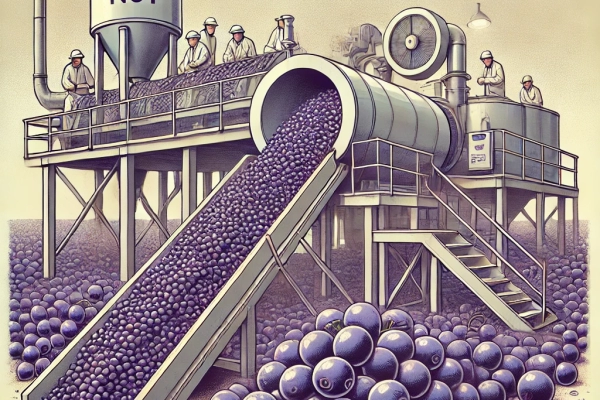

Abrasive Pre-treatment

Abrasive pre-treatment is an optional step in raisin processing that involves gently scrubbing the surface of the grapes to facilitate dehydration.

This process can help remove any waxy coatings on the grapes’ surface, allowing for more efficient drying.

Washing (Repeated)

After abrasive pre-treatment, the grapes may undergo another round of washing to ensure they are clean and free from any debris or residues.

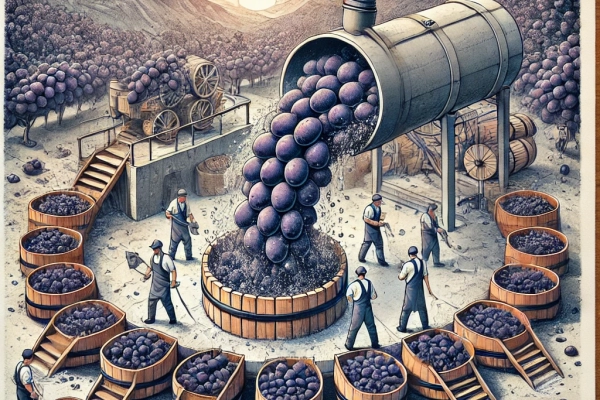

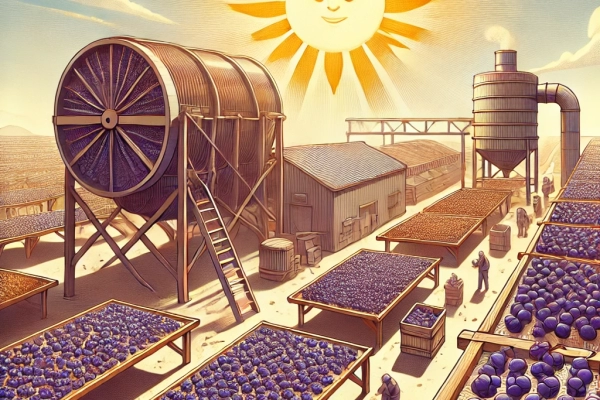

Drying

Once cleaned, the grapes are laid out on trays or racks and placed in the sun to dry.

Alternatively, mechanical drying methods such as using hot air may be employed.

The drying process typically takes several days to a few weeks, during which the grapes gradually lose moisture and become raisins.

Packaging

Once fully dried, the raisins are sorted and graded based on size, color, and quality.

Any imperfect or damaged raisins are removed during this stage.

Finally, the raisins are packaged into various sizes and types of containers, including boxes, bags, or trays, ready for distribution and sale.